EF-Electric kiln

Electrically heated ovens can be used in a variety of ways in industry, crafts and hobbies, for drying, as glass, enamel or ceramic kilns, as laboratory ovens, in dental technology, but also for hardening and tempering and also for forging.

All of the devices listed here are operated with single-phase alternating current 230 volts, which means they can be used practically anywhere.

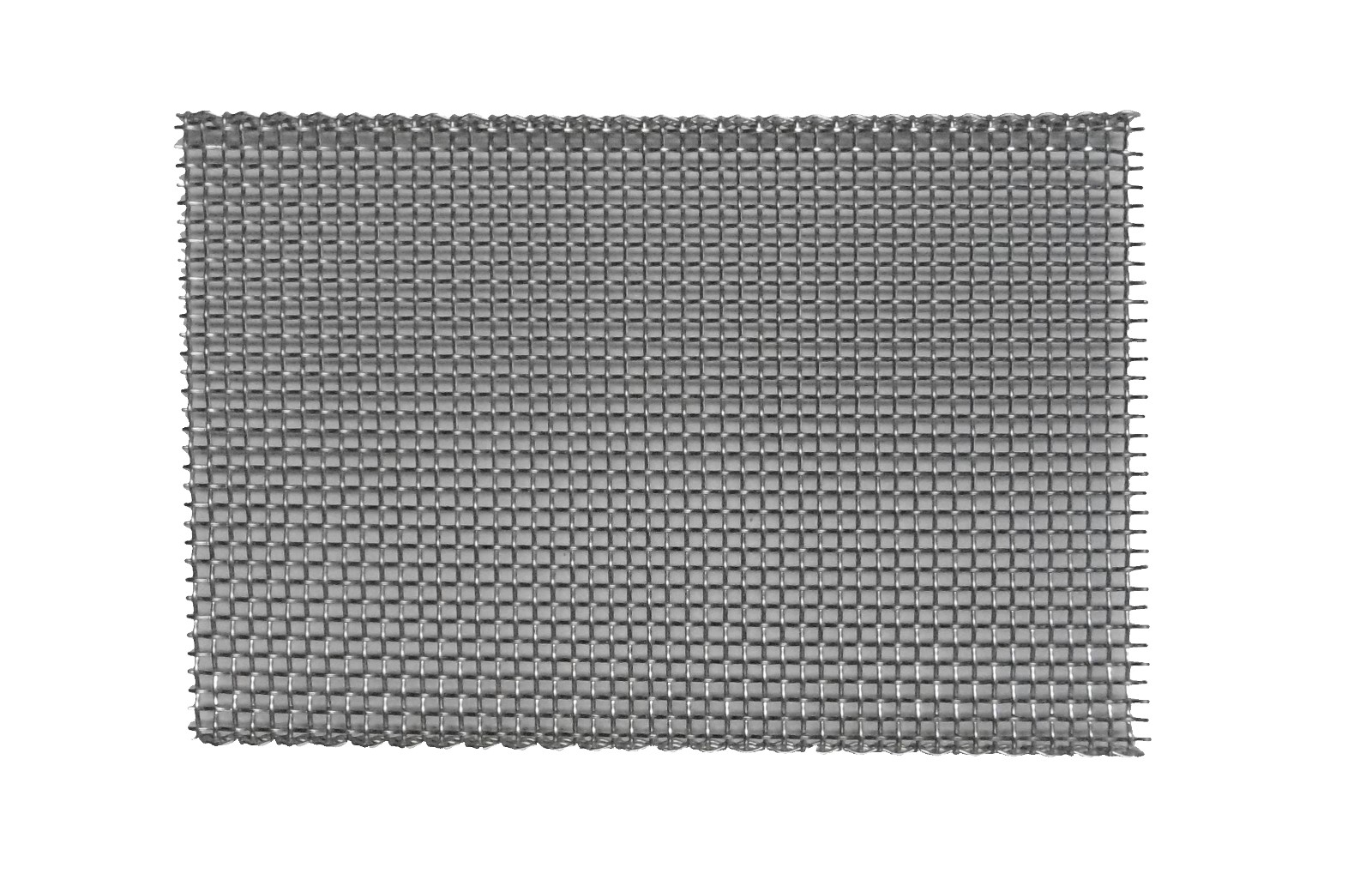

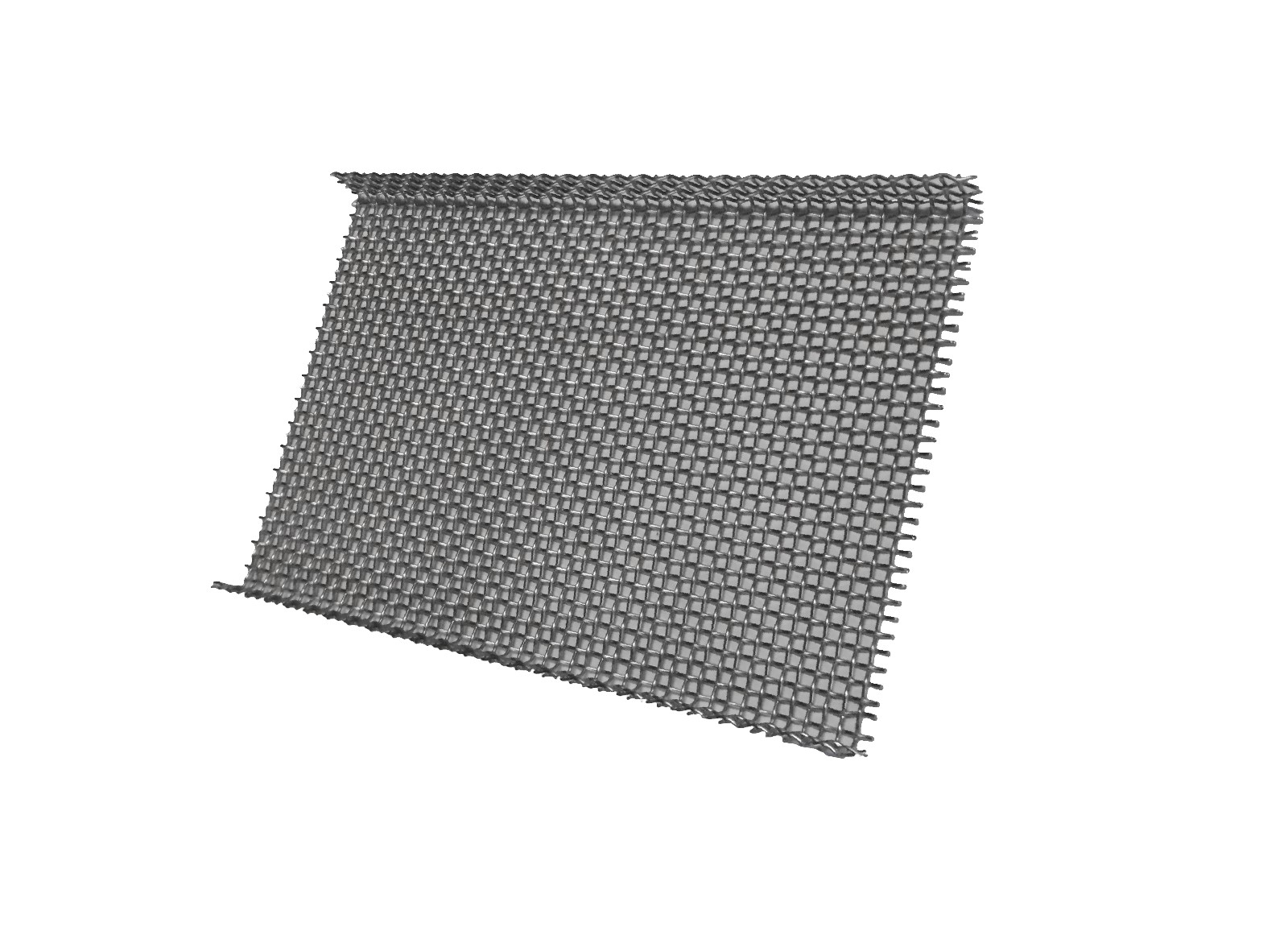

The electric heating coils are not visible in the combustion chamber but are integrated into the ceramic combustion chamber with all-round heating. This makes working easier and more safe. All devices are equipped with a door that swings upwards and has a large viewing window.

These ovens can be used in temperatures from 400 to 1100 °C.