Forks & Tongs

Especially when casting, and especially when handling crucibles, it is important to have a firm and secure grip.

With suitable and sturdy tongs, the crucibles can be handled safely and the crucible will not be damaged.

For example, special tongs are required for every situation, for example, to lift the crucible out of the furnace or to use it for later casting.

We also manufacture special tongs in our workshop for a wide variety of requirements.

Crucible Tongs & Fork

Volker Allexi demonstrates how casting with "ECOCAST®" works at the casting course in Hennef 2013.

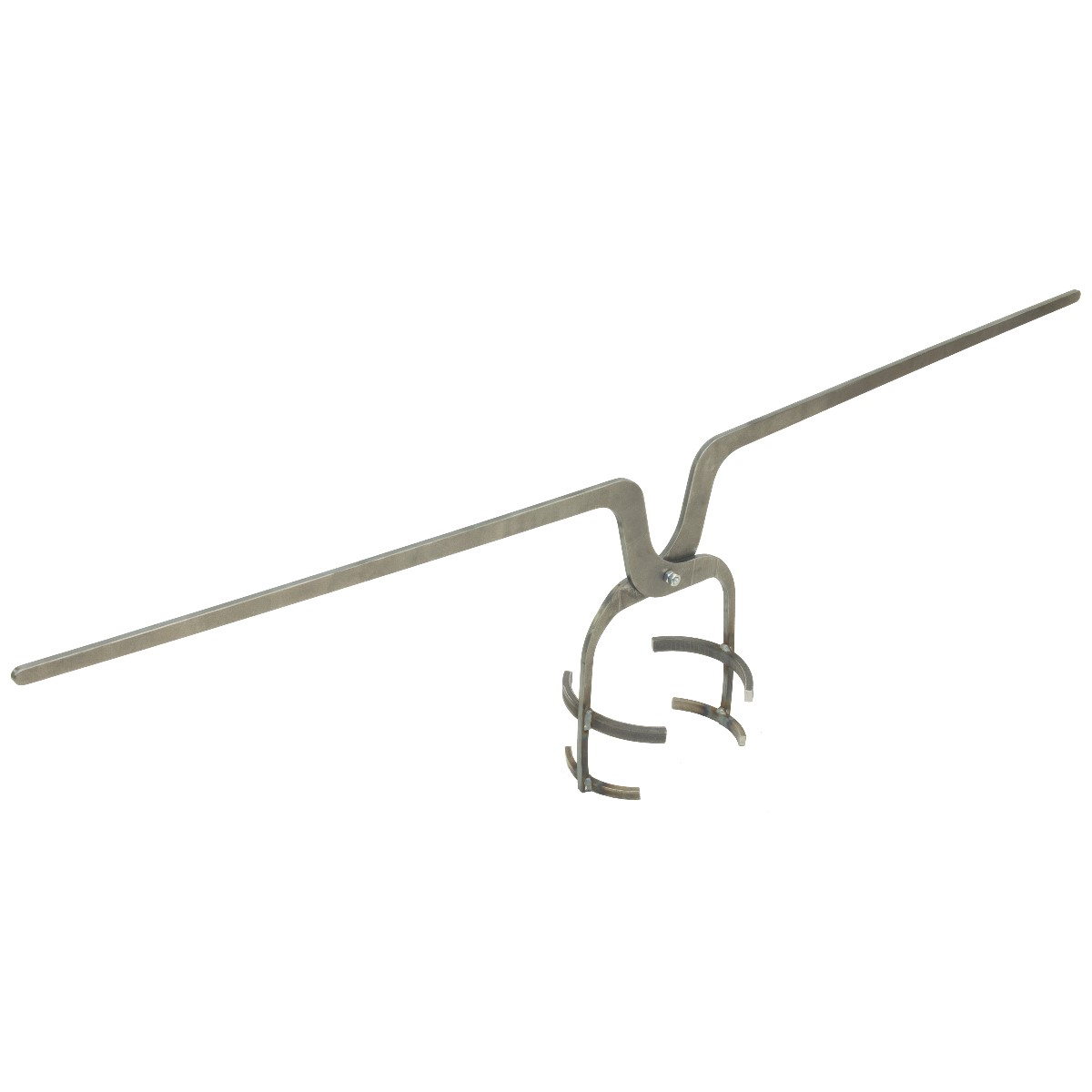

After melting, the crucible is removed from the furnace with tongs and placed in a suitable carrying fork to pour the melt.

Here you can clearly see the areas of application for each pair of tongs and fork. Front-loading furnaces require different tools than top-loading furnaces.

Questions - Answers - FAQ

Many questions about our crucible tongs and forks, which we try to answer without meaningless AI texts.

Do you still have questions? Then feel free to ask us directly here:

Email:

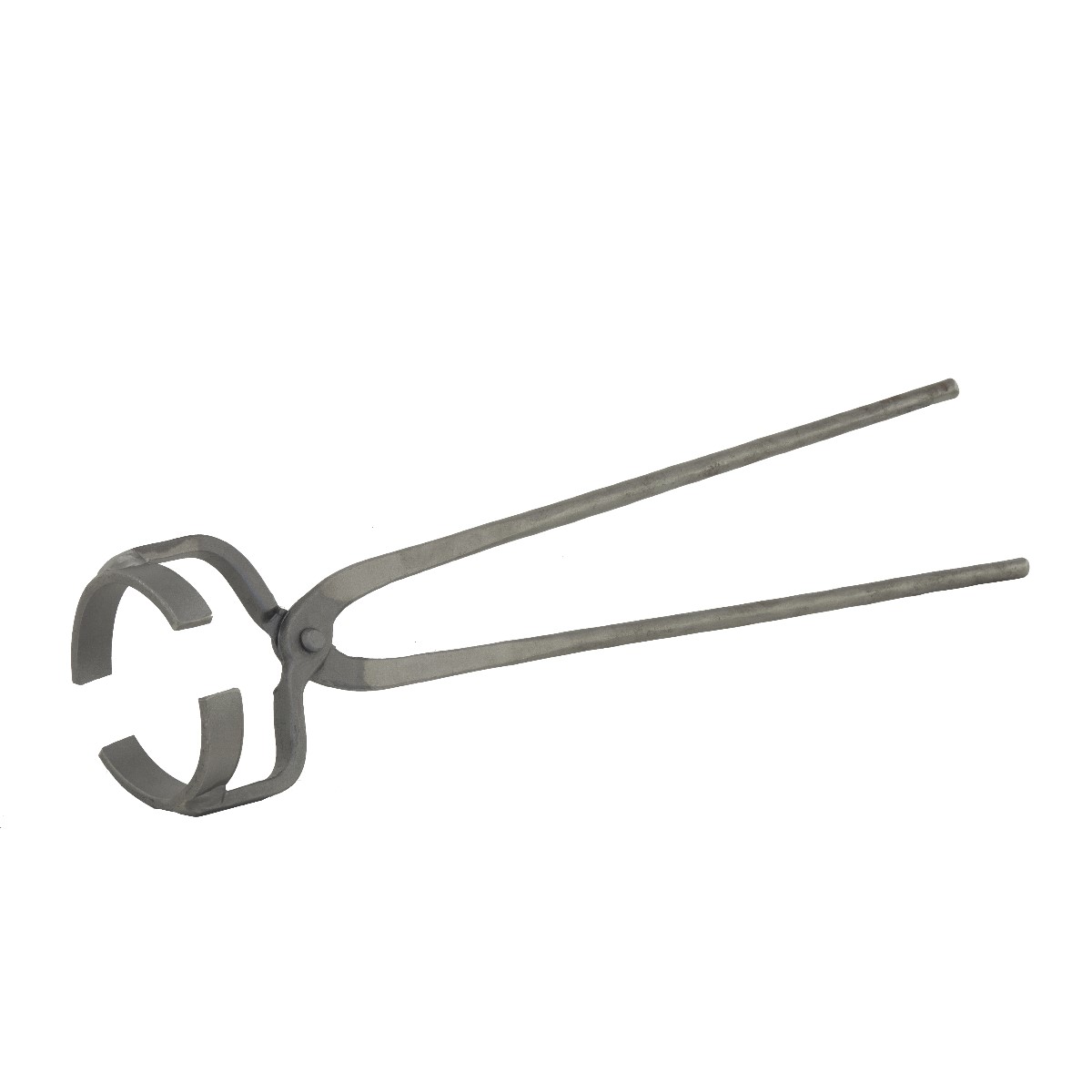

What is a hand-held crucible tong?

Hand-held crucible tongs are used to remove crucibles from the furnace.

They grip the crucible and allow for safe handling.

This type of tong is generally used for crucibles up to 8 kg, as they can still be easily removed from the furnace by one person.

For heavier crucibles, scissor-type crucible tongs are used.

What are scissor-type crucible tongs used for?

Scissor-type crucible tongs are used to remove crucibles from the furnace.

They grip the crucible and allow for safe handling.

This type of tong is generally used for crucibles weighing 15 kg or more, as two people are required to ensure safe handling.

What are crucible holding tongs?

With crucible holding tongs, crucibles can be removed from front-loading furnaces, conventional forge furnaces, or field forges. These tongs allow for direct pouring without the use of a pouring holder.

Unfortunately, this type of tong is not suitable for top-loading furnaces.

For crucibles weighing approximately 4 kg or more, these tongs are also no longer suitable, as the crucible can no longer be handled safely.

What is a pouring holder?

The crucible is placed in the pouring holder, allowing safe pouring.

These holders are used for crucibles weighing up to approximately 8 kg.

Heavier crucibles are poured using a crucible carrying fork and a pair of people.

What is a crucible fork?

A crucible fork is used by two people to cast crucibles weighing up to approximately 50 kg.

The crucible fork is placed in a special fork stand.Do I need to use suitable tongs?

Yes, otherwise the crucibles won't be held securely.

This will damage the crucible, and in the worst case, the crucible and its melt will slip out of the tongs or fork. We don't need to describe the consequences...

What should I look for in crucible tongs or a fork?

Or how do I find suitable tongs?

The tool should grip the crucible tightly. This is the only way to ensure that the crucible is held securely.

A robust design is also important, as it remains stable even when exposed to heat.