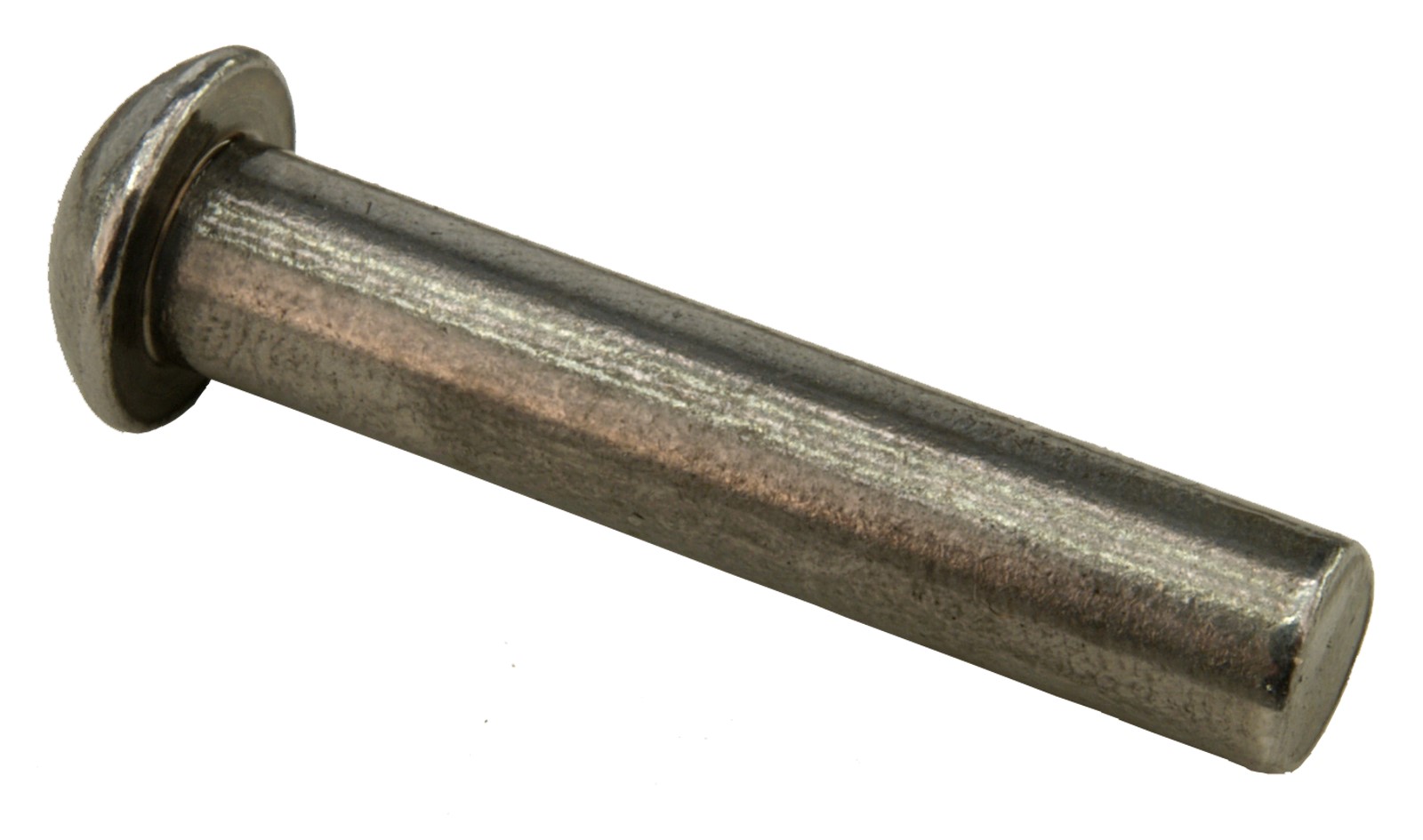

Rivet

The rivet is used to permanently join components together.

During the riveting process, the rivet is inserted through the pre-drilled holes in the components to be joined. Then, with the help of a rivet head maker, the protruding shaft-shaped end of the rivet is formed into the so-called closing head.

Depending on whether the riveting is hot or cold, a positive or non-positive connection is created.

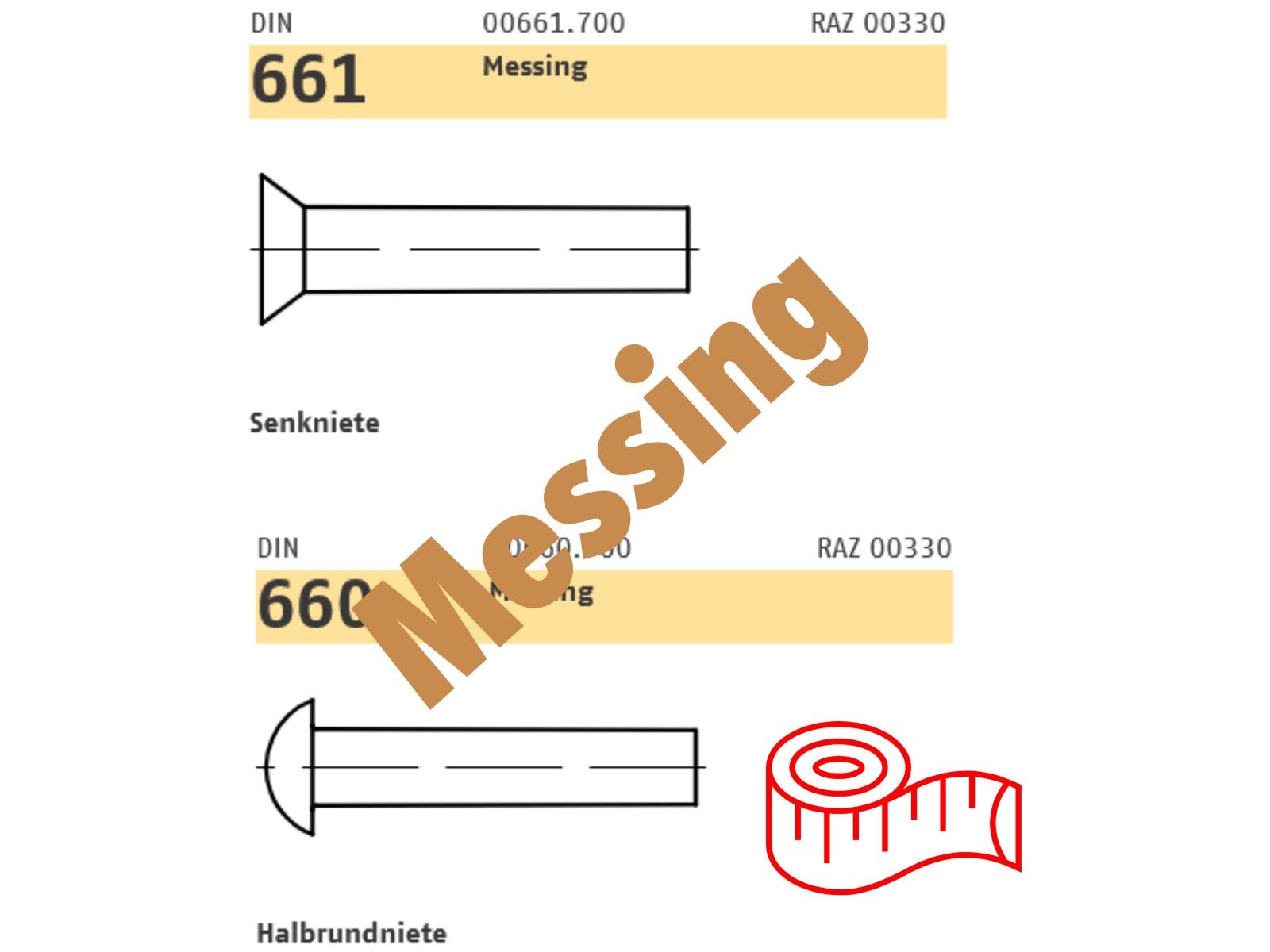

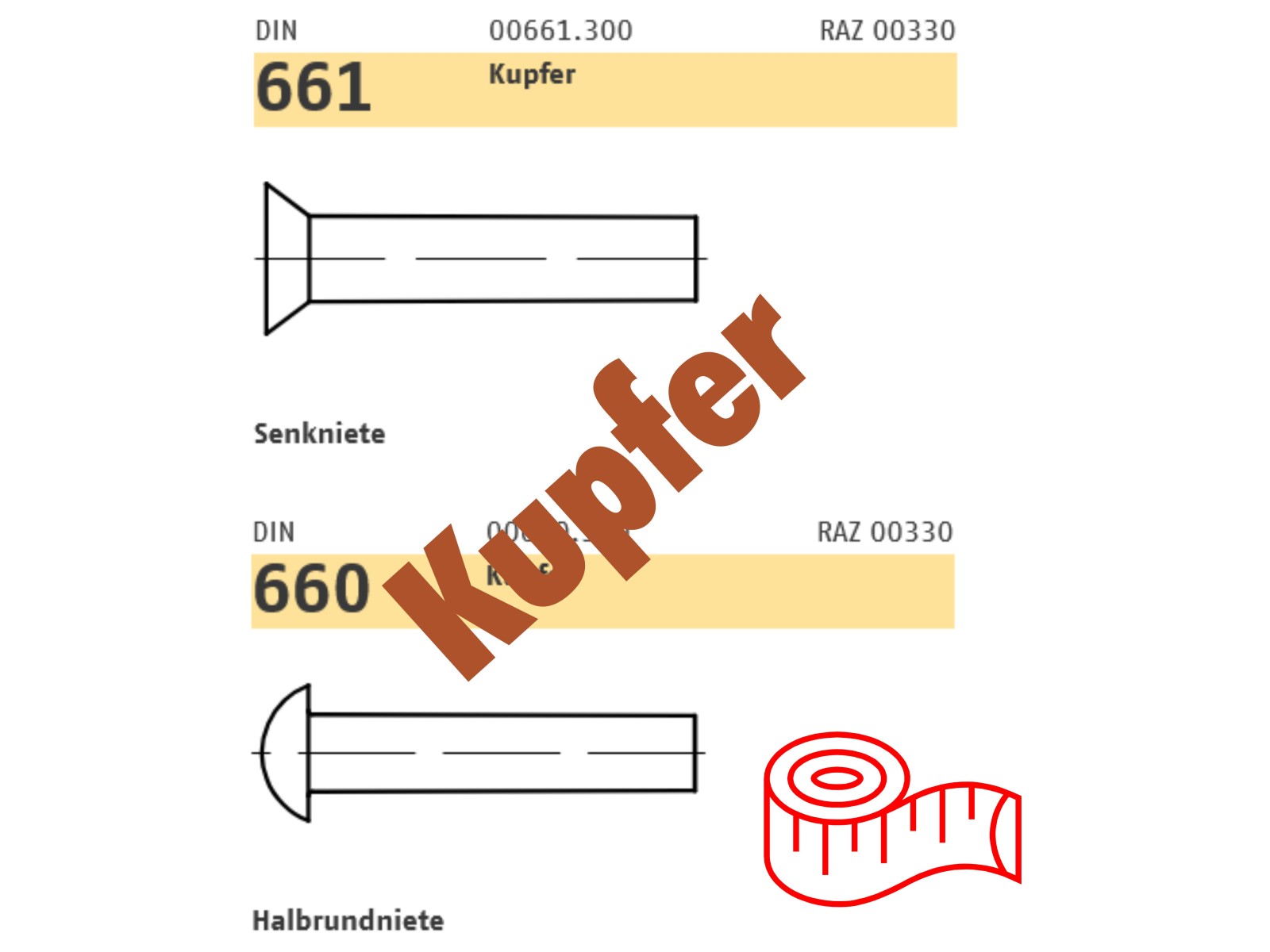

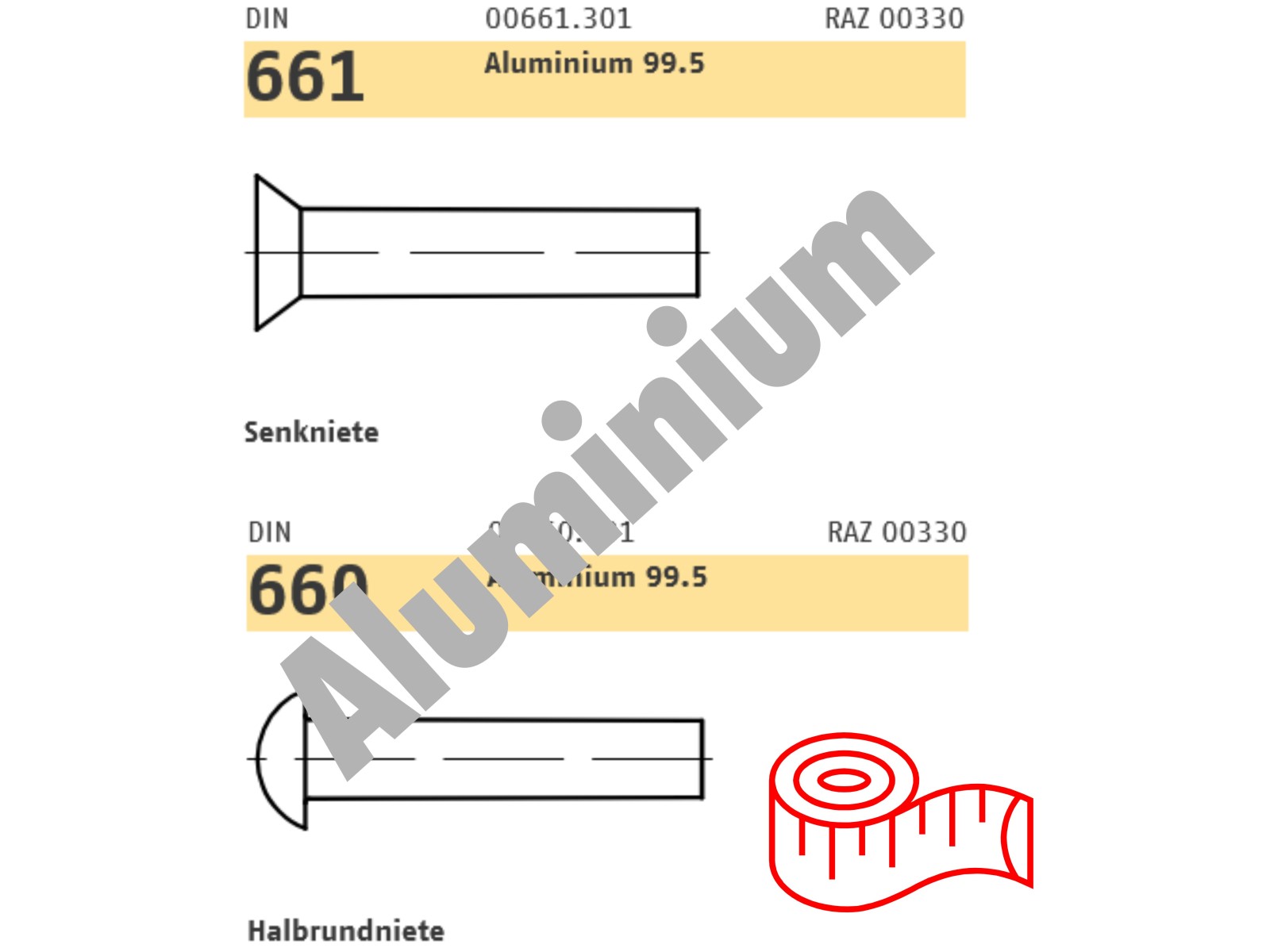

In addition to half-round and countersunk head rivets made of steel, you will also find the appropriate tools and special rivets made of aluminum, copper, or brass here.

How the rivet length is calculated and useful information about rivets can be found further down on this page.

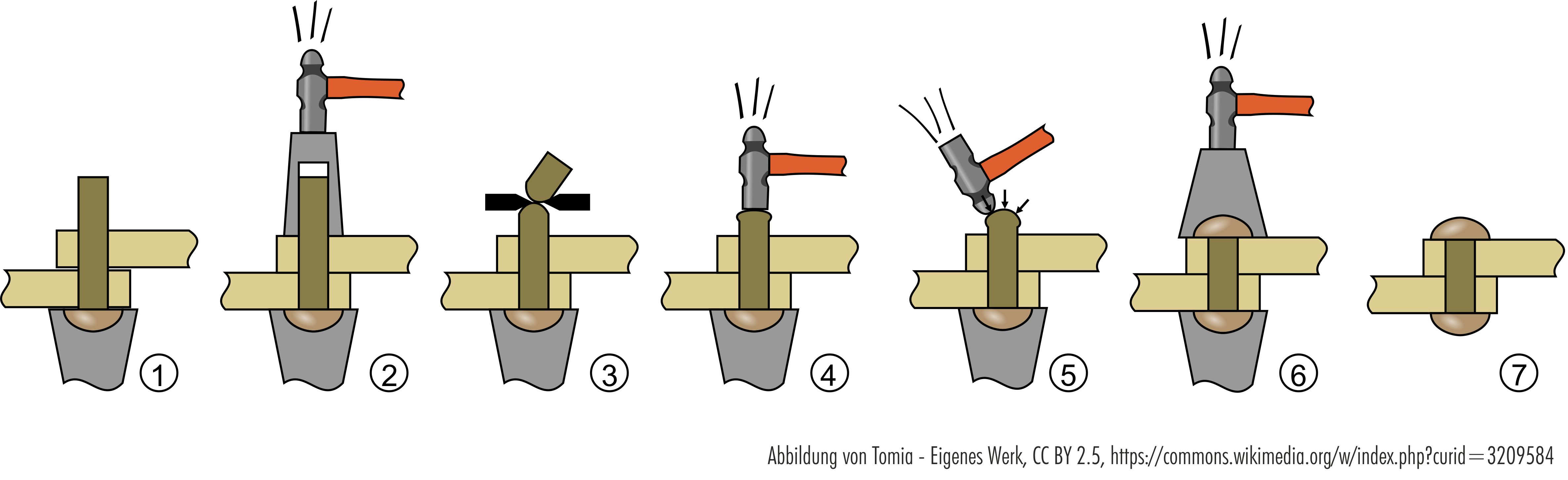

The riveting process

- Insert the rivet into the holes and place it on a counterholder or base.

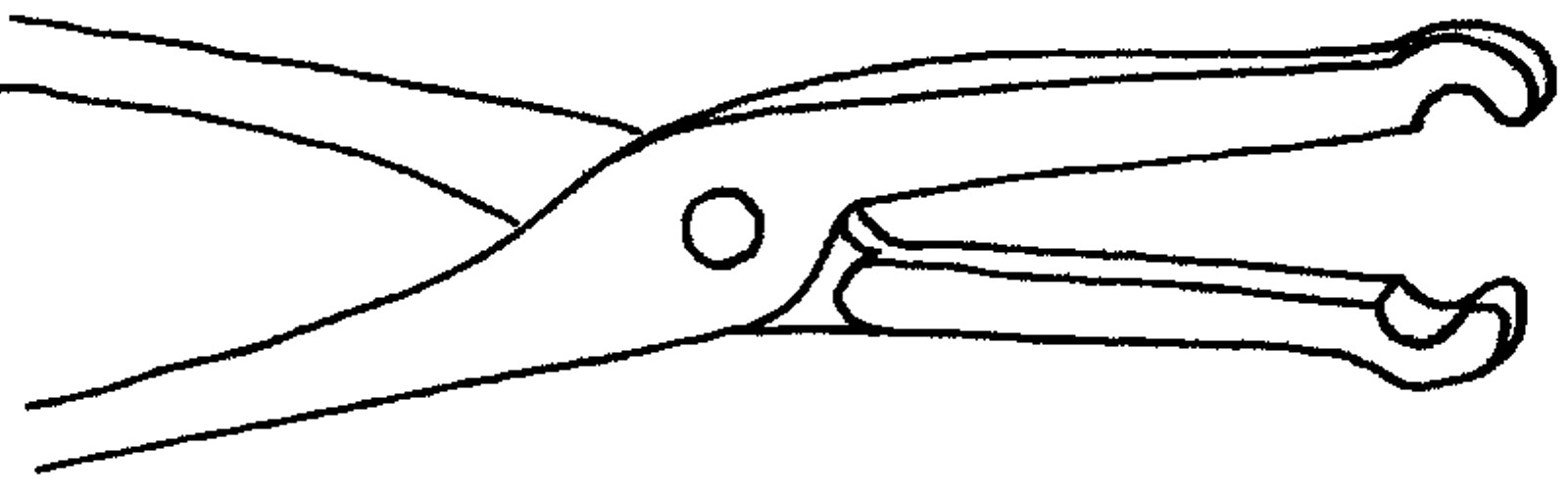

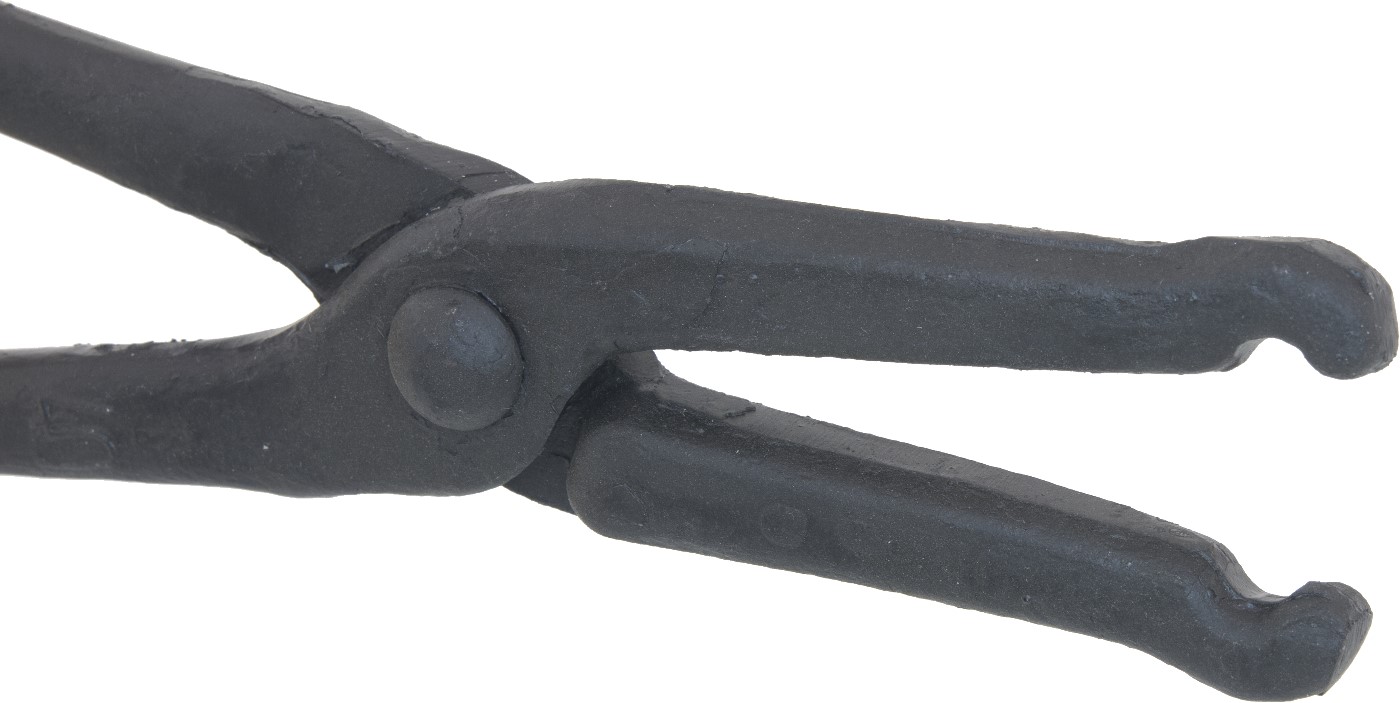

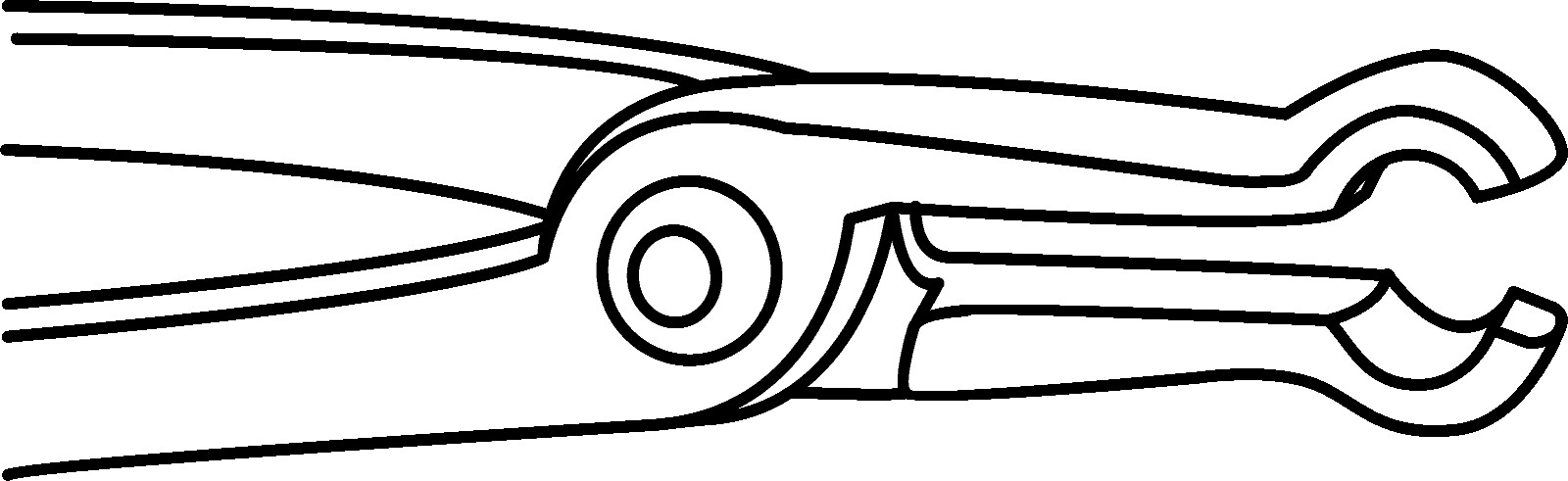

- Press the material flat against each other using the rivet puller.

- Shorten (if the correct length could not be selected, see below).

- Upset the rivet shank.

- Pre-form the rivet head using circular blows with the ball-head hammer.

- Finally form the rivet head using the head maker.

- Done!

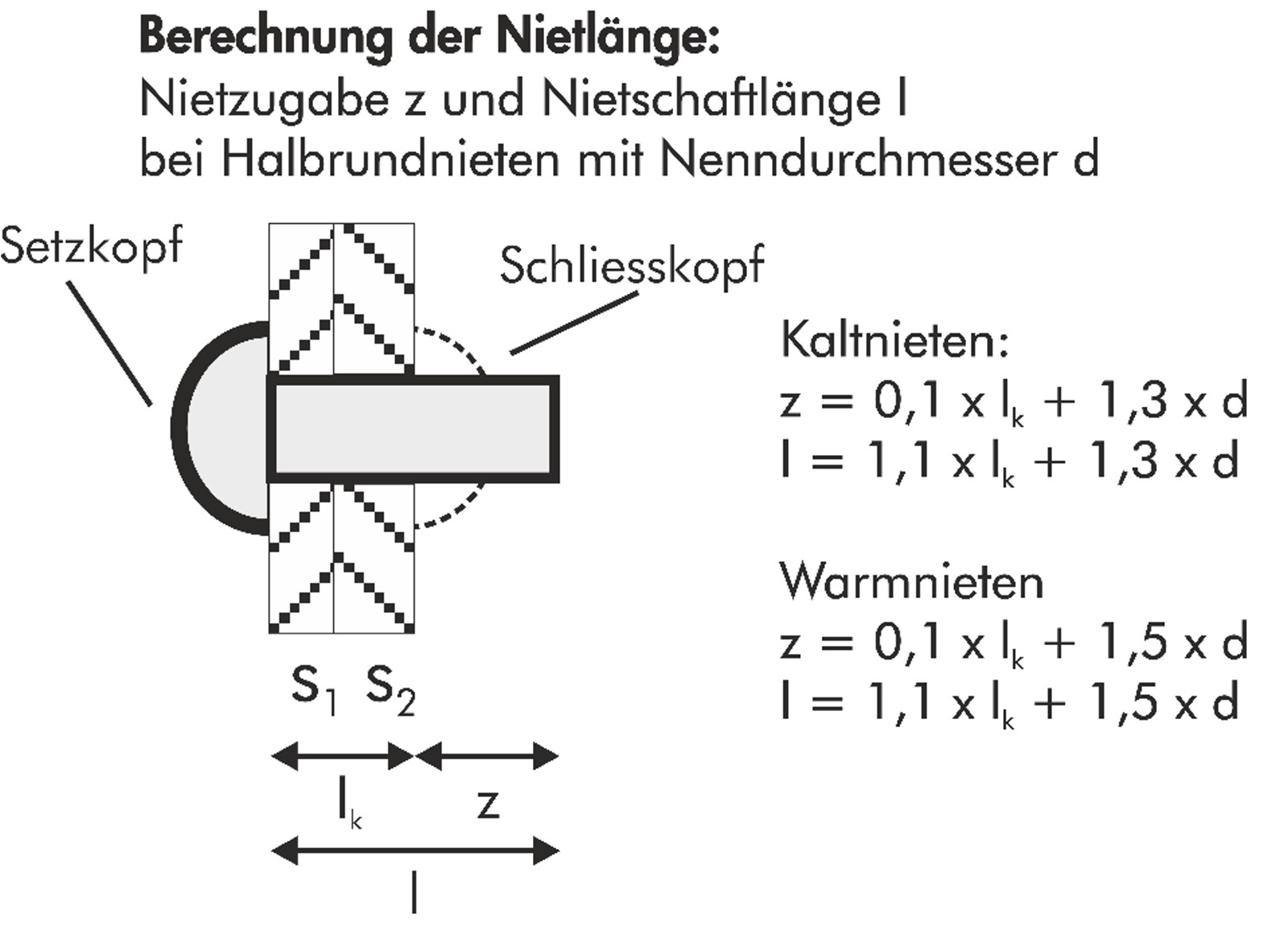

Calculating Rivet Length

The required total length can be calculated based on the thickness of the components to be joined and the shank thickness used. It also depends on whether cold or hot riveting is used.

Normally, only "small" rivets are cold riveted; from a shank diameter of 8-10 mm, hot riveting is recommended. Of course, larger rivets can also be deformed using brute force.

In principle, however, there is also a static/technical difference in the connection. With hot riveting, the rivet contracts again as it cools, pressing the components firmly together (positive connection). With cold riveting, this contraction is missing; only a "positive" connection is created.

Making a riveted joint

The film shows in detail the individual steps involved in making a riveted joint.

It also shows common mistakes when making riveted joints.

Questions - Answers - FAQ

Many questions about the topic of Rivets, to which we try to give answers and without meaningless AI texts.

Do you still have questions? Then please ask us directly here:

E-mail:

What is a rivet?

Everyone knows the rivets you see at fairs, but this has nothing to do with them.

A rivet is a cylindrical fastener that, through plastic deformation, creates an indetachable connection between flat material pieces lying on top of each other, such as sheet metal, plastics, leather, or textiles. This process is called riveting.

What are rivets designated?

Note on the designation: The first number indicates the shaft diameter, the second the shaft length (excluding the head height!).

Accordingly, for example, a rivet DIN 660 - 5 x 10 has a shaft diameter of 5 mm and a shaft length of 10 mm.

The total length of the rivet in this case is 13 mm.

Where to buy rivets?

We offer many different sizes, even in smaller quantities.

Our rivet range offers a perfect starting point and foundation, so you'll always have the right rivet in your drawer.

Making rivets?

Can I make rivets myself?

YES

We have the right tools for this in our range.

You can find the riveting iron here:

Custom rivet - right size?

Can't find the right size?

We can produce all possible sizes for you.

Of course, this is usually only worthwhile for larger quantities.

Just ask us.

What material are rivets made of?

Rivets are made of various materials.

Rivets are made of:

- Steel

- Aluminum

- Brass

- Copper

- Plastic

Steel rivets are mainly used in forging.

Cold or Hot Riveting?

Normally, only small rivets are cold riveted; from a shank diameter of 8-10 mm, hot riveting is recommended. Of course, larger rivets can also be deformed using brute force.

Hot Riveting = Frictional Connection

With hot riveting, the rivet contracts again as it cools and presses the components firmly together (frictional connection).

Cold Riveting = Positive Connection

With cold riveting, the rivet does not "contract," and only a "positive" connection is created.

Is there a standard (DIN) for rivets?

Of course, there is a standard here too (DIN/ISO/...)

Half-round rivets up to Ø 8 mm = DIN 660

Half-round rivets from Ø 8 mm = DIN 124

Countersunk rivets = DIN 661

The Rivet(s)? (m/f/d)

Or what is the correct term?

The or the rivet (plural rivets) in technical terms

or rivets (plural rivets)

Excerpt from https://de.wikipedia.org/wiki/Niet, accessed on March 26, 2025