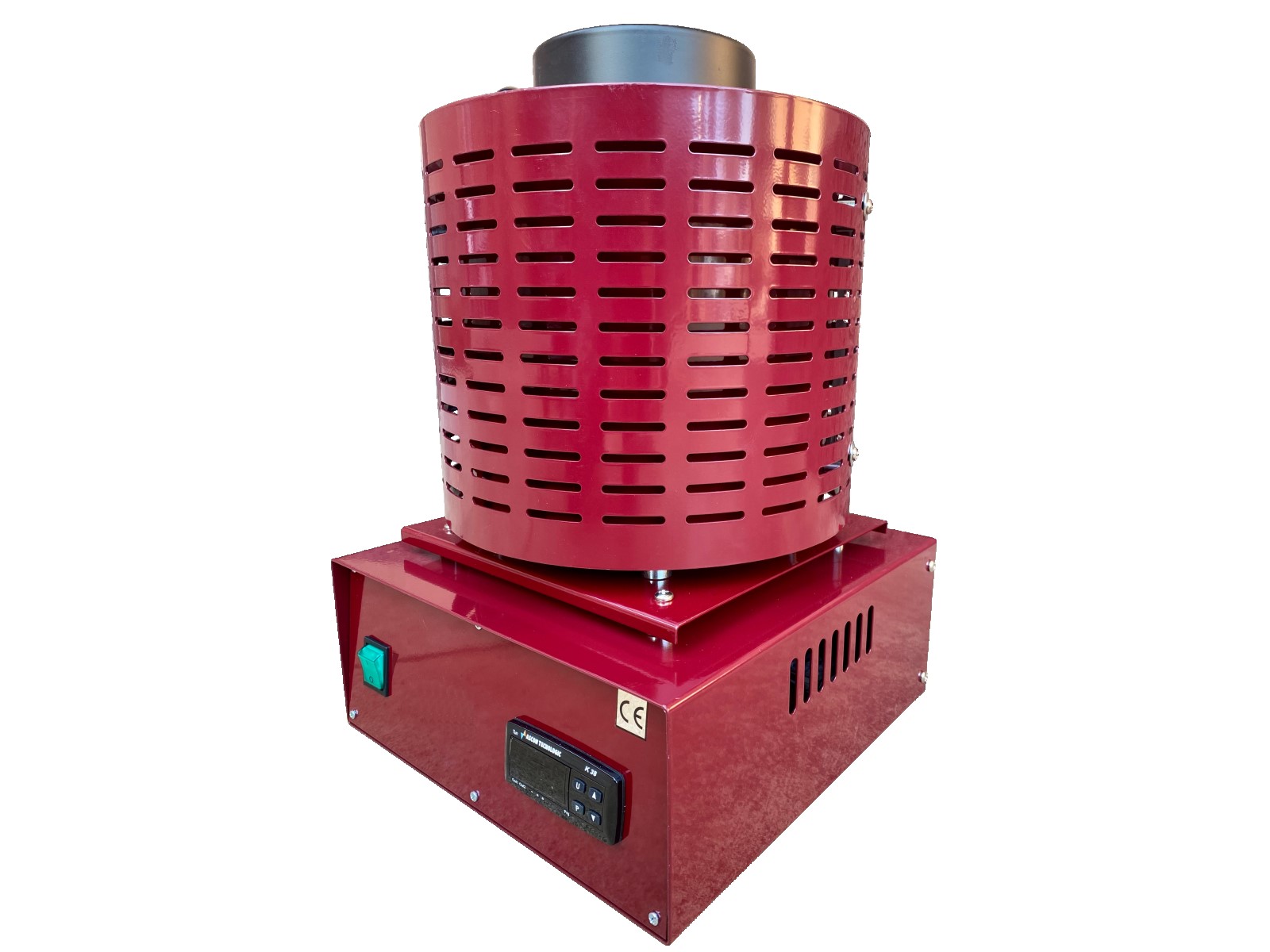

Melting furnace

Questions - Answers - FAQ

Many questions about the topic of melting furnaces, to which we try to give answers and without meaningless AI texts.

Do you still have questions? Then please ask us directly here:

E-mail:

What is a melting furnace?

In a melting furnace, the material is melted using a crucible.

The furnace is also called a crucible furnace.

What types of melting furnace are there?

We have different types of melting furnaces:

- Propane gas powered melting or crucible furnaces

-Electric powered furnaces

It can also be melted using an induction device.

Similarly, the coal furnace or gas furnace can be used for casting

Buy a melting furnace or crucible furnace?

We have various furnaces in our range.

We would be happy to advise you on what is suitable for your project or application.

Which melting or crucible furnace is better?

Gas, electric, induction, or?

There is no direct answer here.

We would be happy to advise you on what is suitable for your project or application.

Melting or crucible furnace for small projects?

We recommend an electric furnace here?

This is easy and safe to use and is quickly ready for use.

This type of furnace is also well suited for school lessons or projects with children.

We would be happy to advise you on what is suitable for your project or application.

What should you look for when buying a melting or crucible furnace?

Here we recommend a furnace that has been tested and not a Chinese product!

Vevor, Aliexpress and whatever they are called offer devices with a CE mark.

However, these devices do not have a real CE mark, but the "CE" stands more for "Chinese export".

The devices work but are catastrophic in terms of safety.

In the event of damage, no manufacturer accepts responsibility for these devices.

It is therefore important to go for tested and reputable manufacturers when buying.