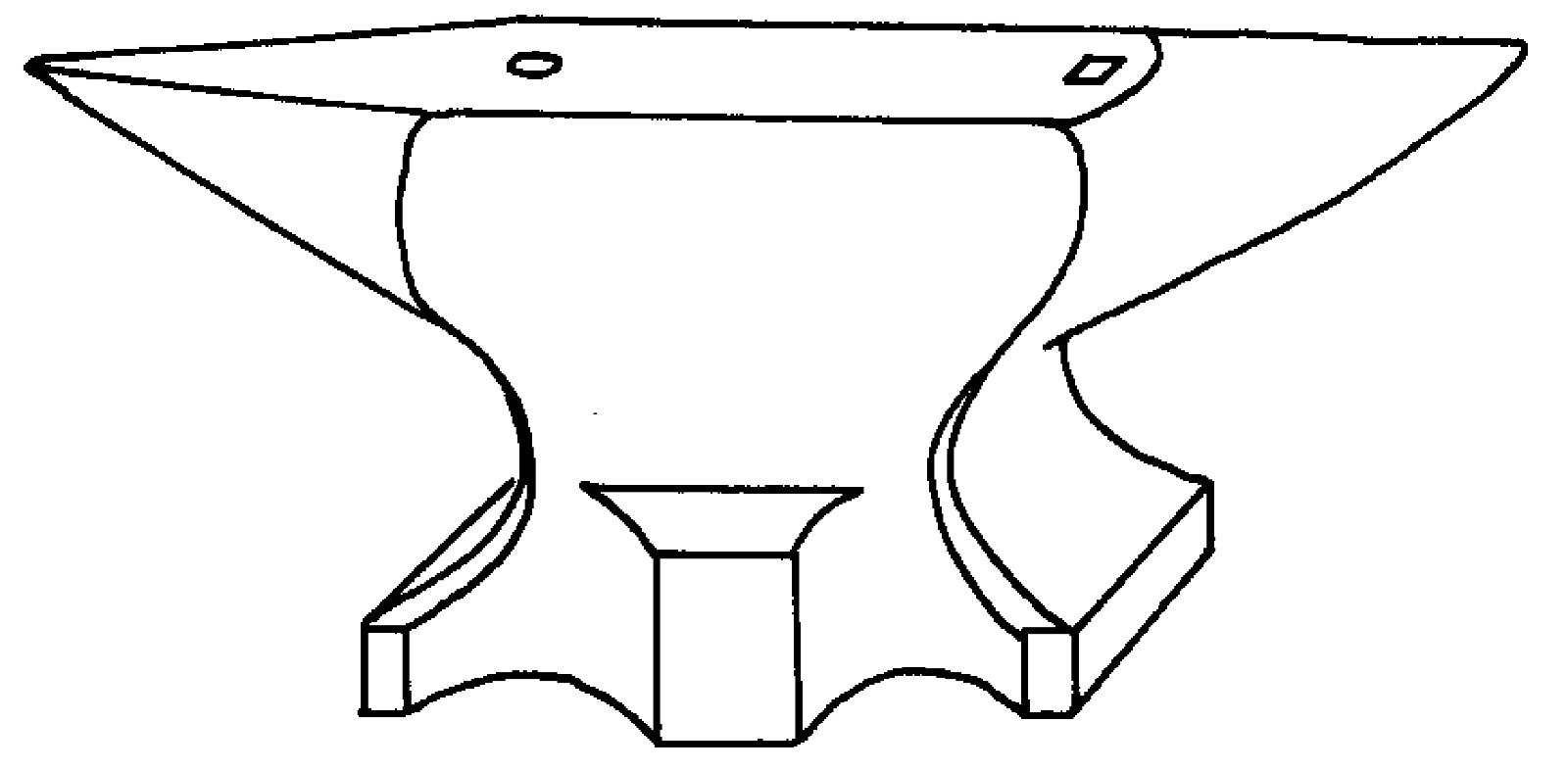

Anvil

The anvil is one of the most important tools in the forge.

In the past, the large anvils consisted of several parts that were welded together in the fire. A steel plate was then welded on to create a high-quality and hardenable track. Finally, the track was hardened.

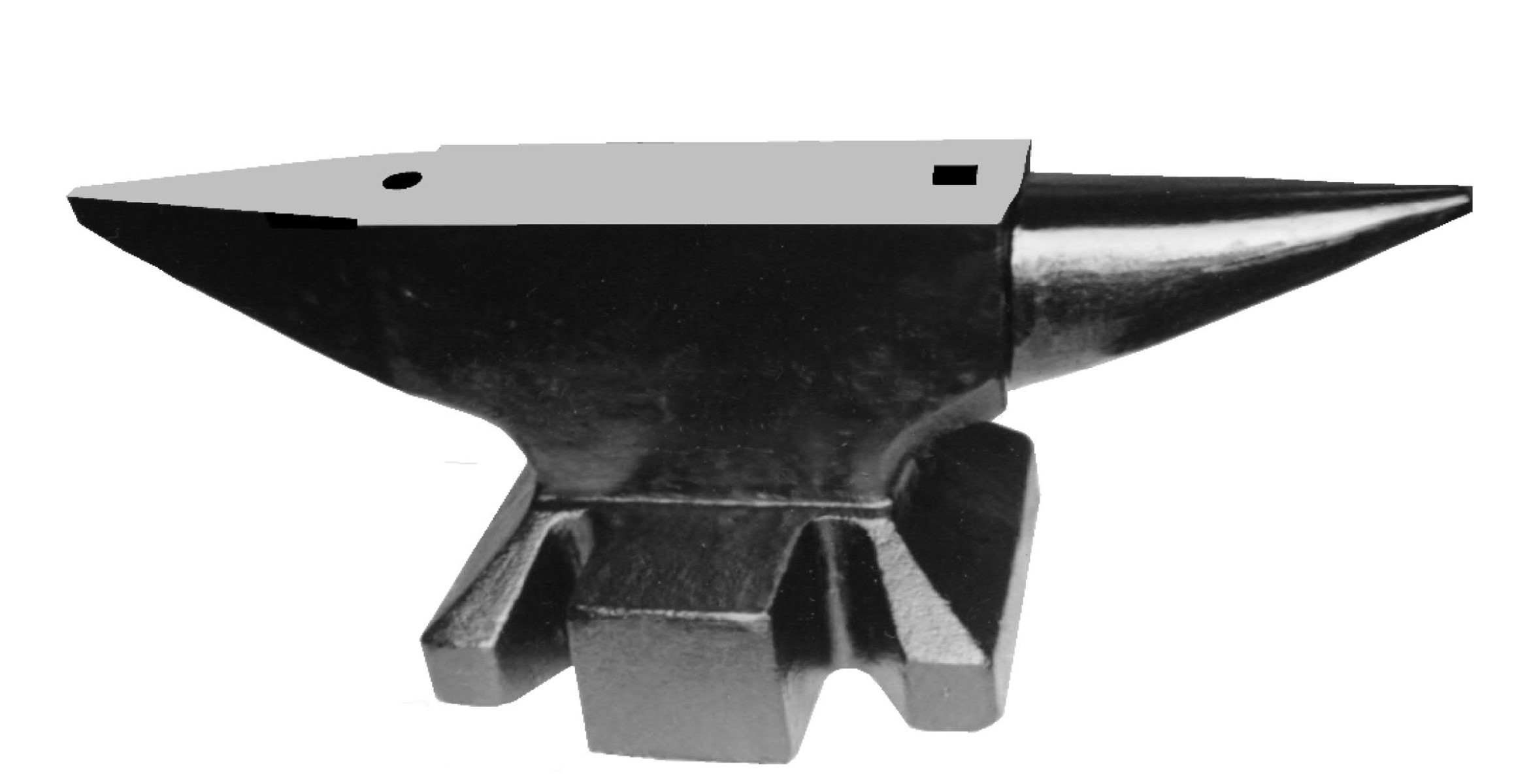

Today, most anvils are made of alloyed cast steel, which is laboriously hardened in the track area - this achieves just as good a quality as the old anvils.

A wide variety of anvil shapes have developed in different regions, with certain shapes having advantages and disadvantages depending on the activity. For example, the heavy, slim anvils with the tapered horns are suitable for artistic forging of large objects. A knife maker, on the other hand, is more likely to work with a 50 or 80 kg anvil with a wide track.

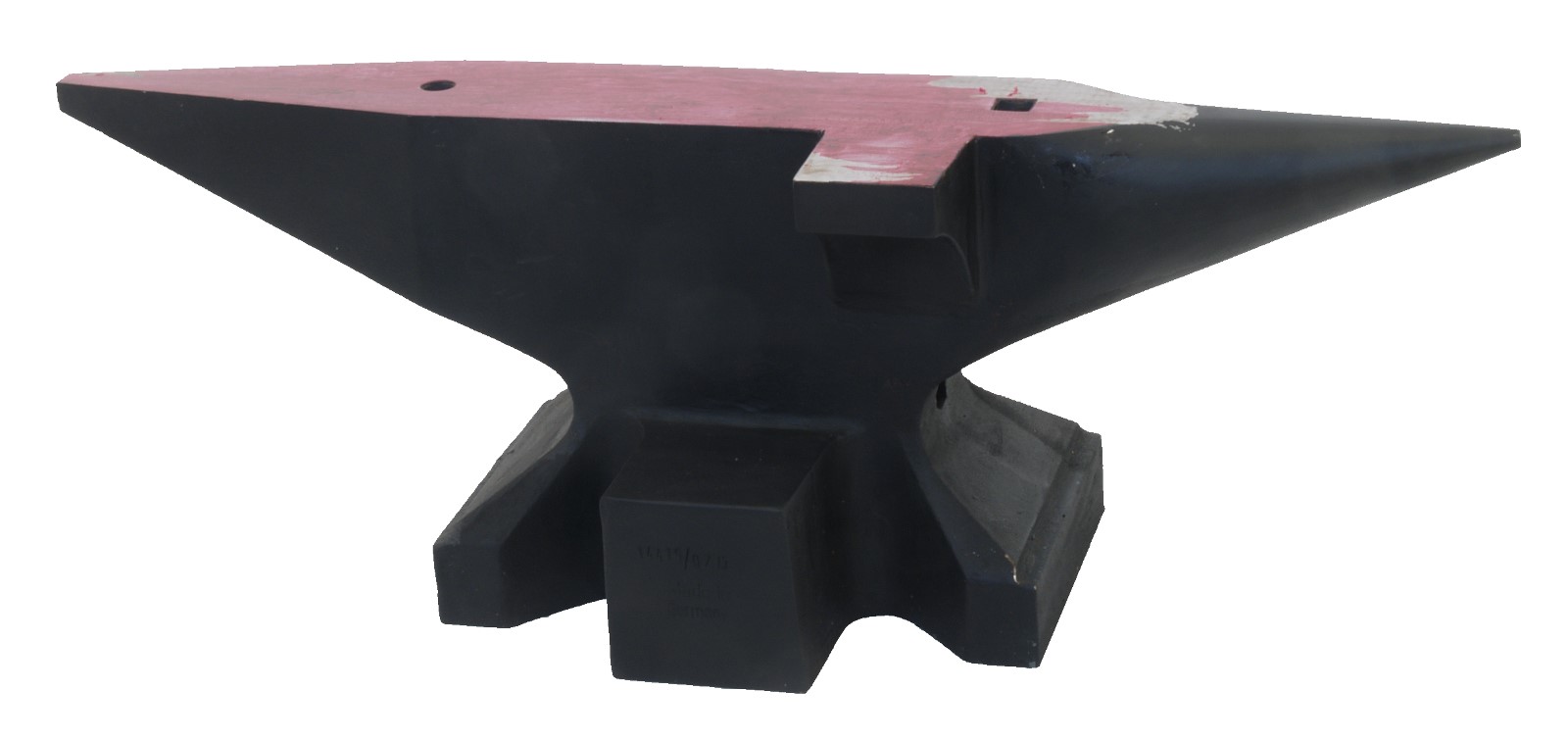

Special - Anvil

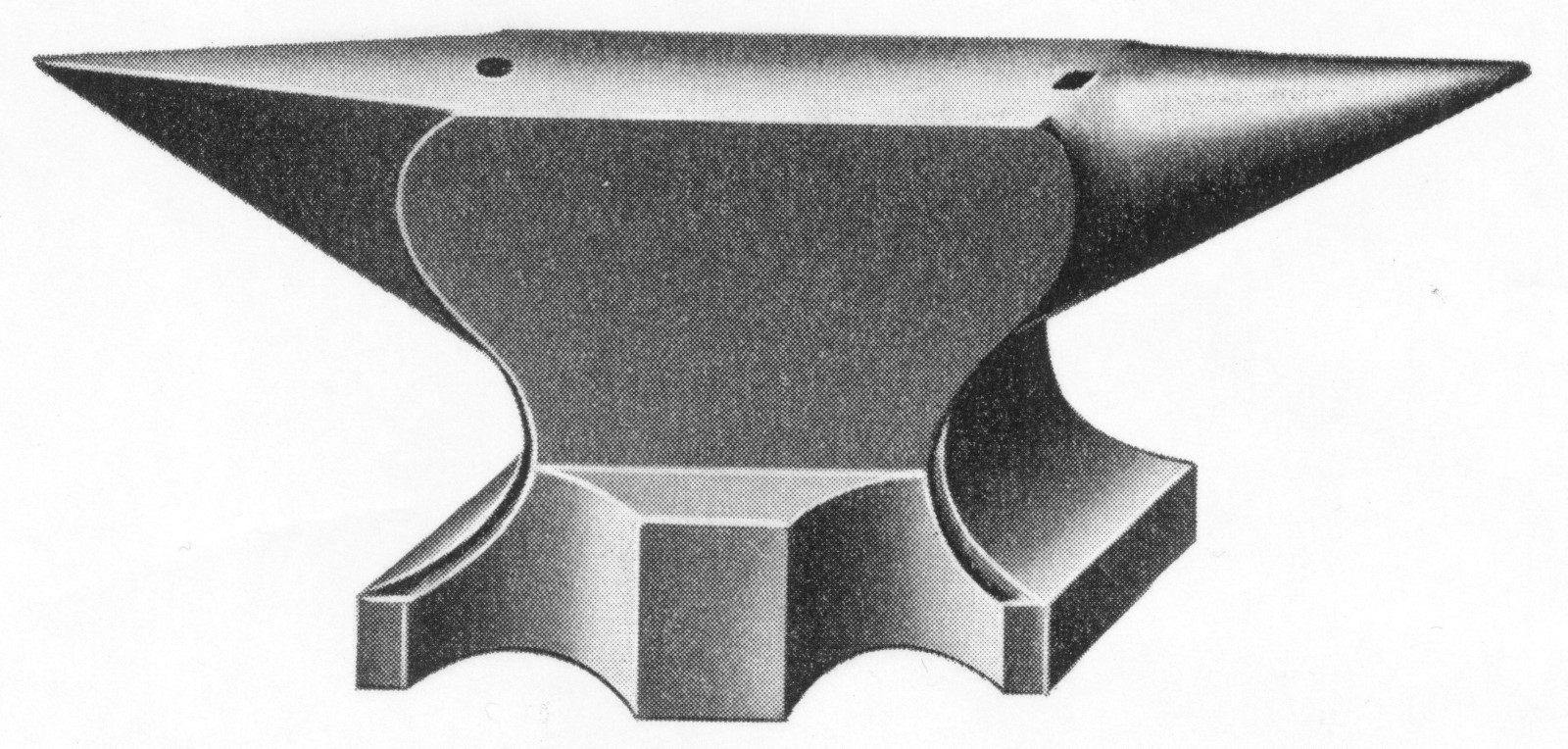

Here you can see how a Hofi anvil is worked on. A pre-anvil, a compression horn, a round horn and a square horn are used for work. The anvil stands on a tripod and you can therefore stand close to the anvil. The height is ideally adapted for the blacksmith to enable ergonomic work.

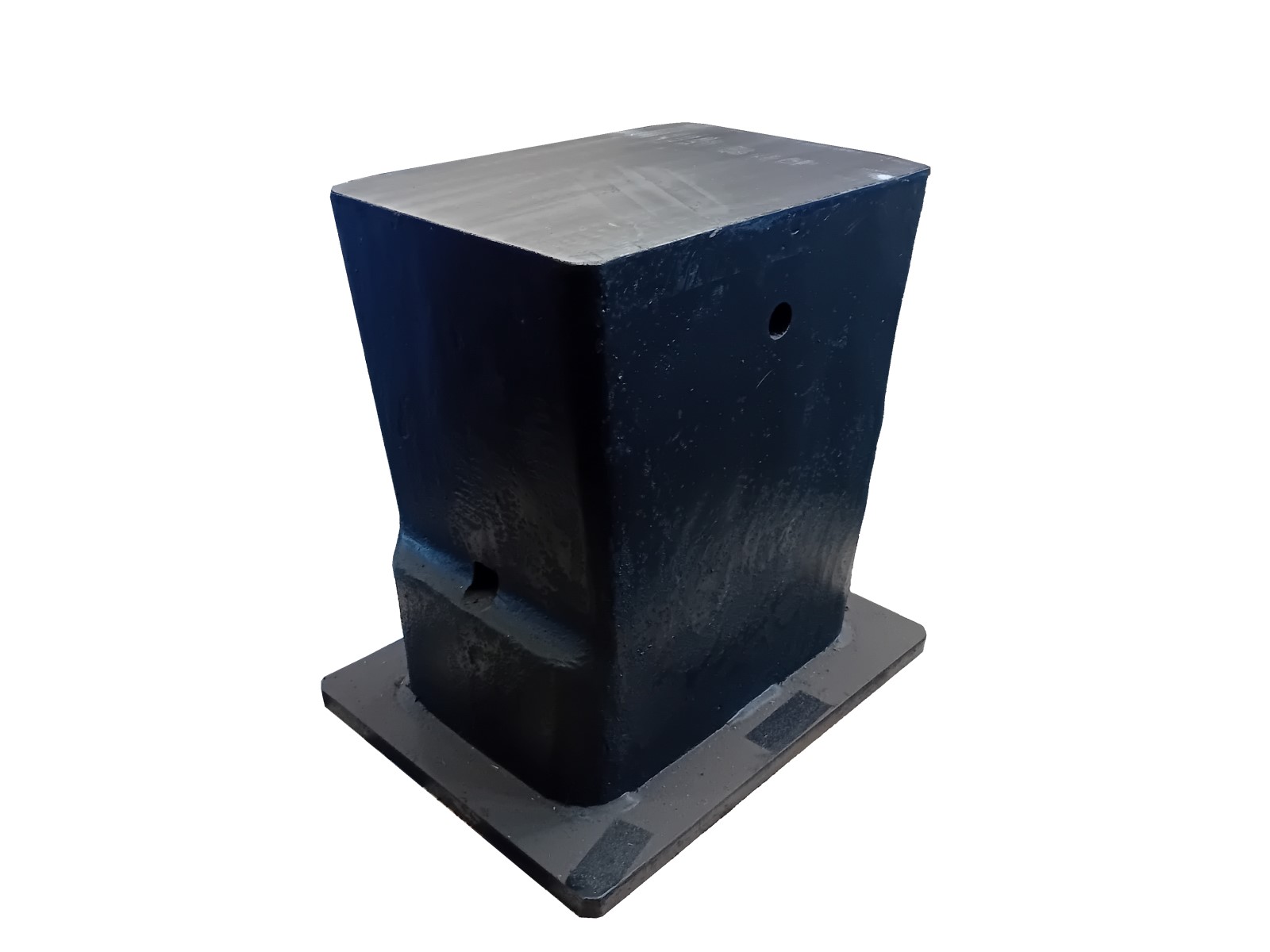

The shape of the anvil shown is similar to the South German and Habermann anvils.

Unfortunately, both are no longer available, but our "B&W anvil" is designed based on these two originals.

You can find this

here

Questions - Answers - FAQ

Many questions about the topic of Amboss, to which we try to give answers and without meaningless AI texts.

Do you still have questions? Then please ask us directly here:

E-Mail:

How heavy does an anvil have to be?

An anvil should have the right weight for its actual use in the forge.

A knife maker, for example, does not need a heavy anvil, as there is hardly any major forming work to be done here. A wider and longer track is more advantageous here.

A farrier needs a lighter, compact anvil that can be easily transported.

A blacksmith who also carries out larger forming work on the anvil needs an anvil that is heavier so that he can also work well with aggregate.

Just ask us and we will help you make your decision.

Which anvil is right for me?

Here you should ask yourself questions in advance such as:

- how big/heavy are my workpieces?

- does the anvil have to be flexible?

- does the anvil have a fixed place?

- and much more...

We will be happy to advise you further and help you make a decision.

What can I do about a ringing anvil?

A ringing, clanking anvil is annoying.

Don't worry, you don't have to buy a new anvil.

A magnet, placed in the right place, works wonders and creates a beautiful sound.

What do I have to look out for when buying?

Here you should make sure that the anvil is reliably hardened and has good workmanship.

Unknown manufacturers and suppliers such as Temu, Aliexpress and other online sources usually sell poor quality from India or other countries. These are usually made of a cast alloy that is not suitable for anvils.

How hard should an anvil be?

An anvil should have a hardness of around 56-60 HRC on the track.

Important: Too hard is not good, as there is a risk that the edges will break or splinter.

A slightly softer anvil is often not a problem, as the hot workpiece is soft and should not be hit on the track with a hardened hammer anyway.

Where can I buy an anvil?

Of course from Angele.

We value tested quality from well-known manufacturers and test every anvil before it leaves our factory.

We know that this question is "strange", but Google wants it that way ;)

What shape should an anvil have?

Here too, there is no right or wrong. Choose the shape that suits your work.

A knife maker usually does not need different round holes or a crimp.

Buying used anvils?

Be careful when buying used anvils. There is a lot of junk on the internet and astronomical prices are being quoted for broken anvils.

When buying, pay attention to how even/flat the track is and how clean the edges are.

Also pay attention to whether there are any cracks or cavities.

Check the hardness of the track.

Ultimately, the price should be right and well below the new price of a comparable anvil.

Can I repair an anvil?

Yes, that is possible. However, there are a few things to consider here so as not to completely ruin the anvil. Only a few people know their craft and repairs are often expensive and time-consuming.

We think it's great to preserve and repair old things, but at a certain point, repairs are neither economical nor sustainable.

What is a good anvil for beginners?

Here an anvil weighing around 50 kg is sufficient.

Here you have the best price-performance ratio and the anvil is easy to move around the workshop.

Here we recommend our

drop-forged anvils

Which anvil for knife makers?

Here we recommend this anvil

Knife-forging anvil

Forged or cast?

In general, there is hardly any difference between a cast and a forged anvil.

The widespread opinion that forged anvils are better is wrong!

This may be true to a certain extent for old anvils. In the past, there were different materials, manufacturing processes and testing methods than today.

With today's manufacturing methods, casting processes and materials, both manufacturing processes are process-safe and deliver very good quality anvils.

All anvils in our range are subjected to quality testing and we have known our suppliers for years.